How Is Bacon Produced?

03/31/2021

Bacon – we know where it goes: in between lettuce and tomato, wrapped around filet mignon, next to eggs-over-easy and on top of everything from cheeseburgers to salad.

But where does bacon come from? How is it made? And should we feel okay about indulging in its crispy goodness? Is bacon sustainably produced?

We traced back to the farm to see what we could learn about bacon’s back story. Good bacon starts with the care of the pigs, said Dr. Joel DeRouchey, an Extension specialist in swine nutrition and management at Kansas State University.

We traced back to the farm to see what we could learn about bacon’s back story. Good bacon starts with the care of the pigs, said Dr. Joel DeRouchey, an Extension specialist in swine nutrition and management at Kansas State University.

“Animal husbandry practices are essential to raising healthy pigs that produce wholesome pork products,” he said.

Animal husbandry includes all the practices that go into caring for the animals.

“This involves a relationship with a veterinarian to help monitor herd health, well maintained housing facilities that provide the proper environment and temperature,” Dr. DeRouchey explained. “Above all, it involves well trained caretakers of the pigs. Pig farmers and their employees go through training in pig care, pig observation and health observation, among many other areas of the Pork Quality Assurance Program.

Pork Quality Assurance is an education program that includes food safety, animal well-being, environmental stewardship, worker safety, public health and community.

It’s well known that pigs like to eat. Their feed is a mixture of ingredients to meet their needs at every stage of growth.

“Pigs eat a nutritionally balanced diet that contains a complete mixture of grain (generally corn but in some locations also wheat or sorghum), protein (generally soybean meal), feed-type amino acids and vitamins and minerals to meet their body needs for growth and health,” Dr. DeRouchey said.

The farm’s location and nearby feed sources also affect pigs’ diet, he explained. Pigs sometimes also eat co-products from corn and wheat processing, bakery food blends from human food processing and fats and oils.

“When pigs are fed a nutritionally balanced diet, they develop the proper lean muscle as they grow which allows them to have the highest quality meat possible. This means minerals such as zinc and various vitamins that make pork more nutritious to eat,” Dr. DeRouchey said.

Pork producers have taken steps to make farming more sustainable. These changes have made it possible to produce more bacon using fewer natural resources.

“A focus on continuous improvement over the past 55 years in raising swine has led to a reduction in land use by 76 percent, water use by 25 percent, decreased energy needs by 7 percent and carbon footprint by 7 percent for every pound of pork produced,” DeRouchey said. Read more.

The pigs also enhance sustainability by producing their own fertilizer.

“Pork producers are dedicated soil conservationists by properly returning manure nutrients to the soil to raise the feed for future pigs and other uses of grains and protein crops,” he said.

Growing crops such as soybeans and corn that pigs eat has also become more sustainable. Crop farmers use practices such as:

- Rotating crops and planting cover crops to improve soil health

- Reducing the amount of tillage or “digging up” the soil

- Using GPS and precision technology to ensure crops receive just what they need at the right time.

Together, these practices make farming more sustainable, which means more bacon with less impact on the environment. Read more.

Once the pigs are fully grown, they are transported to a processing facility where they are harvested. Dr. Travis O’Quinn, associate professor of animal science and industry at Kansas State, explained what happens during processing.

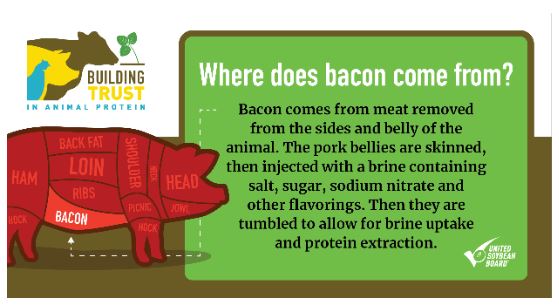

“After the animal is harvested, it is typically chilled for 18 to24 hours. Following chilling, the carcass is broken down into various primal cuts – ham, Boston shoulder, picnic shoulder, loin and belly,” he said.

“After the animal is harvested, it is typically chilled for 18 to24 hours. Following chilling, the carcass is broken down into various primal cuts – ham, Boston shoulder, picnic shoulder, loin and belly,” he said.

Each pig will yield about 130 pounds of retail meat – including 35 pounds of bacon. That’s enough for 175 BLTs!

“Bacon comes from the belly, or the section of meat that is removed from the sides and belly of the animal,” Dr. O’Quinn said. “To produce bacon, bellies are skinned and then injected with a brine solution that contains salt, sugar, sodium nitrate and other flavorings. Then the bellies are typically tumbled to allow for brine uptake and protein extraction.”

Then, the real flavor comes in.

“Following tumbling, the bellies are smoked and cooked in a commercial smokehouse with smoke applied either through natural hardwood smoke or liquid smoke application,” he said.

Different techniques produce various bacon flavors.

“Most commonly, different types of smoke (hickory, apple, maple, etc.) produce different flavors of products. Other times additional flavorings – jalapeno or black pepper – are added on top of the finished bacon immediately prior to packaging,” Dr. O’Quinn explained.

Once the bellies are smoked, they are chilled, pressed, sliced, packaged and transported to restaurants and stores. When looking over those packages of bacon, Dr. O’Quinn shared advice on how to choose the best bacon.

“The key characteristic consumers should evaluate when purchasing bacon should be on the lean-to-fat ratio. Higher amounts of lean and lower amounts of fat in a bacon slice is most desirable,” he said.

Bacon comes from pigs who are cared for on the farm and fed ingredients that are sustainably raised. In processing, the belly is specially prepared to produce wonderful bacon goodness.